Capabilities

DMAero (DMA) offers engineering, technical support, integration, maintenance, modification, and repair to systems and support equipment throughout the lifecycle. We provide our customers optimum engineering bandwidth utilizing a multilayered team that possesses the skills, attributes, and the knowledge to cover any engineering challenge.

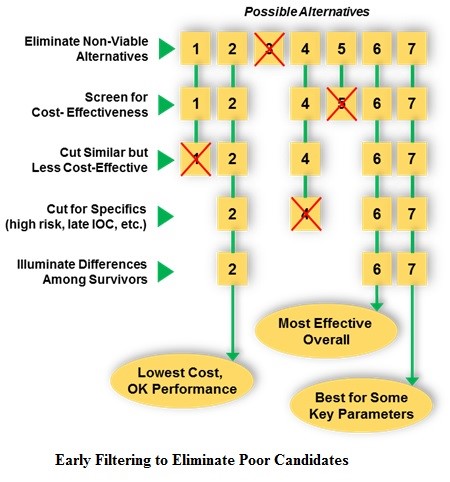

System Design

Whether the new system will reuse current system modules or be a full system design, DMA understands the relationship between various componets and how the completed system interfaces into the system as a whole. We have designed both reuse and complete systems for military applications.

Previous Experiences Include:

- APQ-166 Radar Pressurization Unit (B-52)

- ARC-169 Front Panel (E-3 Sentry)

- Electronic Control Unit and Loader's Weapon Control Panel for the Trainable Gun Mount (C-130)

- Display Software for the Terrain Following Program (MC-130J)

Test and Support Equipment

Independent Verification and Validation (IV&V)

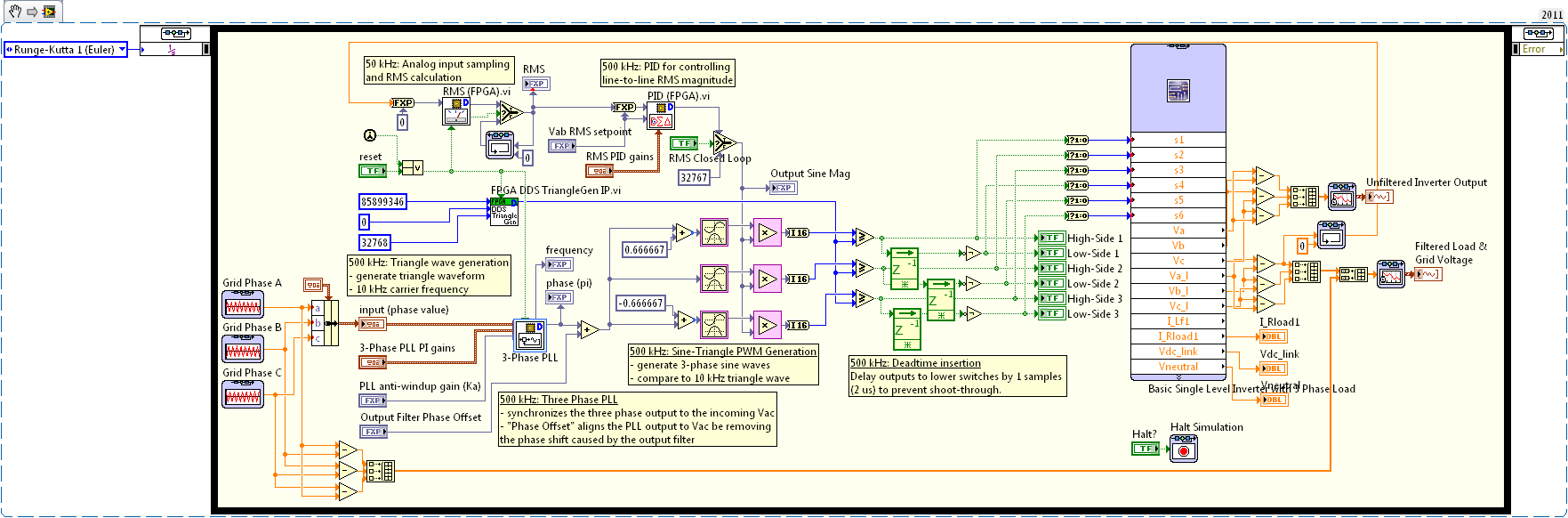

Research and Development (R&D)

Simulation

Logistics

Fabrication & Modification

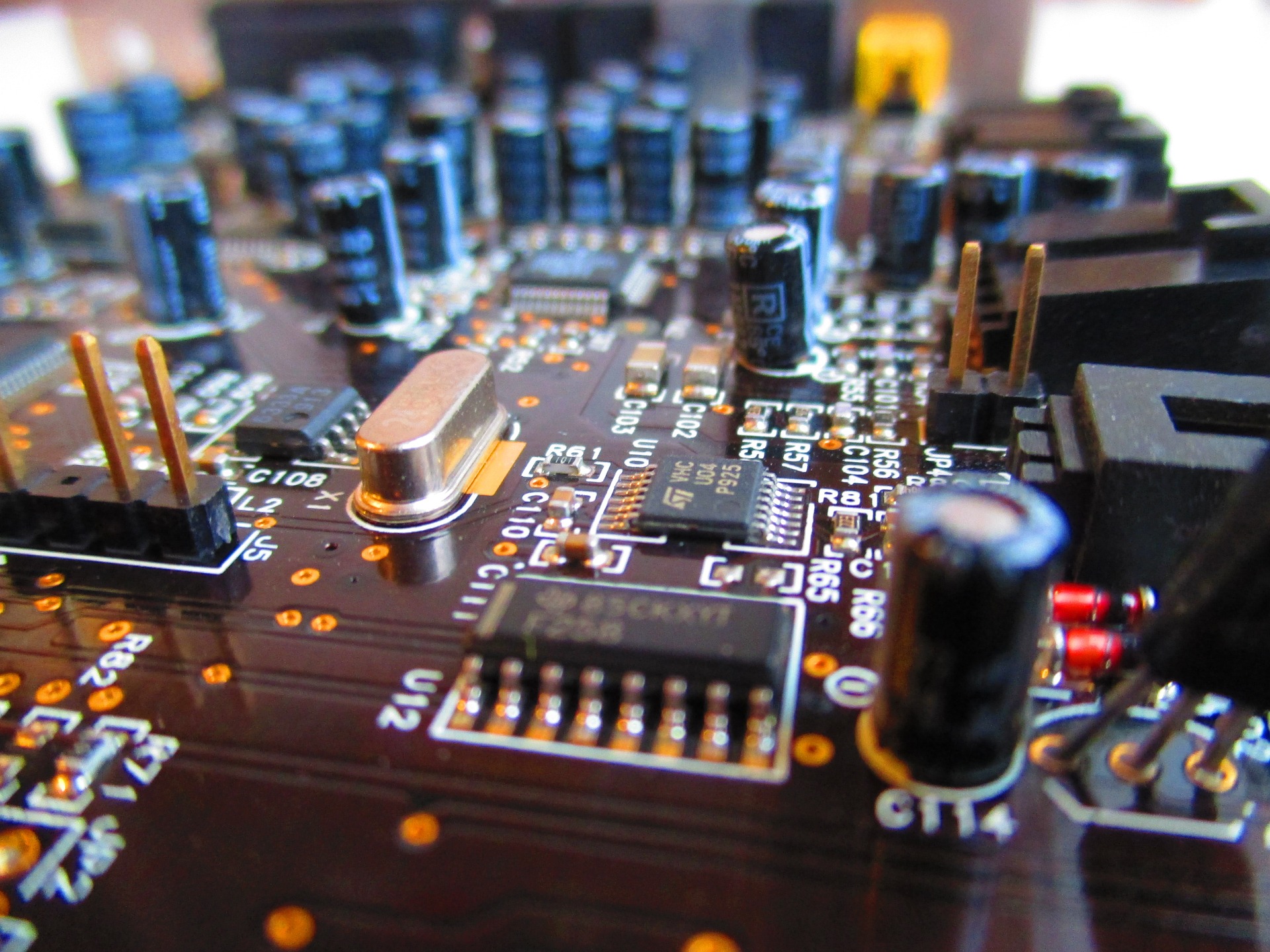

Component Redesign

Integration

Test and Support Equipment

NAICS Codes

- PRIMARY: 541330 - Engineering Services

- 332993 - Ammunition (Except Small Arms) Manufacturing

- 334511 - Search, Detection, Navigation, Guidance, Aeronautical, and Nautical System and Instrument Manufacturing

- 334111 - Electronic Computer Manufacturing

- 335313 - Switchgear And Switchboard Apparatus Manufacturing

- 336413 - Other Aircraft Parts and Auxiliary Equipment Manufacturing

- 488190 - Other Support Activities for Air Transportation

- 511130 - Book Publishers

- 518210 - Data Processing, Hosting, And Related Services

- 541340 - Drafting Services

- 541511 - Custom Computer Programming Services

- 541512 - Computer Systems Design Services

- 541690 - Other Scientific and Technical Consulting Services

- 541715 - Research and Development in the Physical, Engineering, and Life Sciences (except Nanotechnology and Biotechnology)

- 541990 - All Other Professional, Scientific, and Technical Services

- 561410 - Document Preparation Services

- 811219 - Other Electronic and Precision Equipment Repair And Maintenance

PSC Codes

- PRIMARY: R425 - Support- Professional: Engineering/Technical

- AC11 - National Defense R&D Services; Department of Defense - Military; Basic Research

- AC12 - National Defense R&D Services; Department of Defense - Military; Applied Research

- AC13 - National Defense R&D Services; Department of Defense - Military; Experimental Development

- AC31 - National Defense R&D Services; Defense-related activities; Basic Research

- AC32 - National Defense R&D Services; Defense-related activities; Applied Research

- AC33 - National Defense R&D Services; Defense-related activities; Experimental Development

- AR11 - Space R&D Services; Space flight, research and supporting activities; Basic Research

- AR12 - Space R&D Services; Space flight, research and supporting activities; Applied Research

- AR13 - Space R&D Services; Space flight, research and supporting activities; Experimental Development

- B505 - Special Studies/Analysis- Cost Benefit

- B513 - Special Studies/Analysis- Feasibility (Non-Construction)

- B529 - Special Studies/Analysis- Scientific Data

- B539 - Special Studies/Analysis- Aeronautical/Space

- B541 - Special Studies/Analysis- Defense

- B544 - Special Studies/Analysis- Technology

- B599 - Special Studies/Analysis- Other

- DA01 - IT and Telecom – Business Application/Application Development Support Services (Labor)

- DA10 - IT and Telecom - Business Application/Application Development Software As A Service

- DB01 - IT and Telecom - High Performance Computing (HPC) Support Services (Labor)

- H110 - Quality Control- Weapons

- H113 - Quality Control- Ammunition and Explosives

- H114 - Quality Control- Guided Missiles

- H115 - Quality Control- Aircraft and Airframe Structural Components

- H116 - Quality Control- Aircraft Components and Accessories

- H118 - Quality Control- Space Vehicles

- H119 - Quality Control- Ships, Small Craft, Pontoons, and Floating Docks

- H120 - Quality Control- Ship and Marine Equipment

- H123 - Quality Control- Ground Effect Vehicles, Motor Vehicles, Trailers, and Cycles

- H125 - Quality Control- Vehicular Equipment Components

- H159 - Quality Control- Electrical and Electronic Equipment Components

- H210 - Equipment and Materials Testing- Weapons

- H213 - Equipment and Materials Testing - Ammunition and Explosives

- H214 - Equipment and Materials Testing - Guided Missiles

- H215 - Equipment and Materials Testing - Aircraft and Airframe Structural Components

- H216 - Equipment and Materials Testing - Aircraft Components and Accessories

- H218 - Equipment and Materials Testing - Space Vehicles

- H219 - Equipment and Materials Testing - Ships, Small Craft, Pontoons, and Floating Docks

- H220 - Equipment and Materials Testing - Ship and Marine Equipment

- H223 - Equipment and Materials Testing - Ground Effect Vehicles, Motor Vehicles, Trailers, and Cycles

- H225 - Equipment and Materials Testing - Vehicular Equipment Components

- H259 - Equipment and Materials Testing - Electrical and Electronic Equipment Components

- H310 - Inspection - Weapons

- H313 - Inspection - Ammunition and Explosives

- H314 - Inspection - Guided Missiles

- H315 - Inspection - Aircraft and Airframe Structural Components

- H316 - Inspection - Aircraft Components and Accessories

- H318 - Inspection - Space Vehicles

- H319 - Inspection - Ships, Small Craft, Pontoons, and Floating Docks

- H320 - Inspection - Ship and Marine Equipment

- H323 - Inspection - Ground Effect Vehicles, Motor Vehicles, Trailers, and Cycles

- H325 - Inspection - Vehicular Equipment Components

- H359 - Inspection - Electrical and Electronic Equipment Components

- H910 - Other Quality Control, Testing, and Inspection - Weapons

- H913 - Other Quality Control, Testing, and Inspection - Ammunition and Explosives

- H914 - Other Quality Control, Testing, and Inspection - Guided Missiles

- H915 - Other Quality Control, Testing, and Inspection - Aircraft and Airframe Structural Components

- H916 - Other Quality Control, Testing, and Inspection - Aircraft Components and Accessories

- H918 - Other Quality Control, Testing, and Inspection - Space Vehicles

- H919 - Other Quality Control, Testing, and Inspection - Ships, Small Craft, Pontoons, and Floating Docks

- H920 - Other Quality Control, Testing, and Inspection - Ship and Marine Equipment

- H923 - Other Quality Control, Testing, and Inspection - Ground Effect Vehicles, Motor Vehicles, Trailers, and Cycles

- H925 - Other Quality Control, Testing, and Inspection - Vehicular Equipment Components

- H959 - Other Quality Control, Testing, and Inspection - Electrical and Electronic Equipment Components

- J010 - Maintenance, Repair, and Rebuilding of Equipment - Weapons

- J013 - Maintenance, Repair, and Rebuilding of Equipment - Ammunition and Explosives

- J014 - Maintenance, Repair, and Rebuilding of Equipment - Guided Missiles

- J015 - Maintenance, Repair, and Rebuilding of Equipment - Aircraft and Airframe Structural Components

- J016 - Maintenance, Repair, and Rebuilding of Equipment - Aircraft Components and Accessories

- J018 - Maintenance, Repair, and Rebuilding of Equipment - Space Vehicles

- J019 - Maintenance, Repair, and Rebuilding of Equipment - Ships, Small Craft, Pontoons, and Floating Docks

- J020 - Maintenance, Repair, and Rebuilding of Equipment - Ship and Marine Equipment

- J023 - Maintenance, Repair, and Rebuilding of Equipment - Ground Effect Vehicles, Motor Vehicles, Trailers, and Cycles

- J025 - Maintenance, Repair, and Rebuilding of Equipment - Vehicular Equipment Components

- J059 - Maintenance, Repair, and Rebuilding of Equipment - Electrical and Electronic Equipment Components

- J998 - Non-Nuclear Ship Repair (East)

- J999 - Non-Nuclear Ship Repair (West)

- K010 - Modification of Equipment - Weapons

- K013 - Modification of Equipment - Ammunition and Explosives

- K014 - Modification of Equipment - Guided Missiles

- K015 - Modification of Equipment - Aircraft and Airframe Structural Components

- K016 - Modification of Equipment - Aircraft Components and Accessories

- K018 - Modification of Equipment - Space Vehicles

- K019 - Modification of Equipment - Ships, Small Craft, Pontoons, and Floating Docks

- K020 - Modification of Equipment - Ship and Marine Equipment

- K023 - Modification of Equipment - Ground Effect Vehicles, Motor Vehicles, Trailers, and Cycles

- K025 - Modification of Equipment - Vehicular Equipment Components

- K059 - Modification of Equipment - Electrical and Electronic Equipment Components

- L010 - Technical Representative - Weapons

- L013 - Technical Representative - Ammunition and Explosives

- L014 - Technical Representative - Guided Missiles

- L015 - Technical Representative - Aircraft and Airframe Structural Components

- L016 - Technical Representative - Aircraft Components and Accessories

- L018 - Technical Representative - Space Vehicles

- L019 - Technical Representative - Ships, Small Craft, Pontoons, and Floating Docks

- L020 - Technical Representative - Ship and Marine Equipment

- L023 - Technical Representative - Ground Effect Vehicles, Motor Vehicles, Trailers, and Cycles

- L025 - Technical Representative - Vehicular Equipment Components

- L059 - Technical Representative - Electrical and Electronic Equipment Components

- N010 - Installation of Equipment - Weapons

- N013 - Installation of Equipment - Ammunition and Explosives

- N014 - Installation of Equipment - Guided Missiles

- N015 - Installation of Equipment - Aircraft and Airframe Structural Components

- N016 - Installation of Equipment - Aircraft Components and Accessories

- N018 - Installation of Equipment - Space Vehicles

- N019 - Installation of Equipment - Ships, Small Craft, Pontoons, and Floating Docks

- N020 - Installation of Equipment - Ship and Marine Equipment

- N023 - Installation of Equipment - Ground Effect Vehicles, Motor Vehicles, Trailers, and Cycles

- N025 - Installation of Equipment - Vehicular Equipment Components

- N059 - Installation of Equipment - Electrical and Electronic Equipment Components

- R405 - Support- Professional: Operations Research/Quantitative Analysis

- R408 - Support- Professional: Program Management/Support

- R410 - Support- Professional: Program Evaluation/Review/Development

- R412 - Support- Professional: Simulation

- R420 - Support- Professional: Certifications and Accreditations (Other Than Educational Institutions or Info Tech C&A)

- R422 - Support- Professional: Market Research/Public Opinion

- R425 - Support- Professional: Engineering/Technical

- R499 - Support- Professional: Other

- R706 - Support- Management: Logistics Support

- R707 - Support- Management: Contract/Procurement/Acquisition Support

- R799 - Support- Management: Other

NIGP Codes

- PRIMARY: 92503 - Aeronautical and Aerospace Engineering

- 03504 - Aircraft Avionics, (Not Otherwise Classified): Navigation Instruments, Transponders, Global Positioning Systems, etc.

- 03509 - Aircraft Communications Radio

- 03510 - Aircraft Navigation Radio

- 03511 - Aircraft Master Control Systems (Computer, etc.)

- 03515 - Aircraft Radar

- 03544 - Fire Control Systems, Aircraft

- 03546 - Flight Instruments: Airspeed, Altimeters, Attitude and Turn and Bank Indicators, etc.

- 03547 - Flight Simulator

- 03560 - Instruments and Testers, Airplane

- 03565 - Instruments and Testers, Helicopter

- 03594 - Warning Systems, Aircraft: Emergency, Fire, Escape, Ejection, etc.

- 20515 - Aviation Software, Flight Control, Ground Support, Testing, etc., Microcomputer

- 22030 - Indicating and Recording Instruments, Equipment and Accessories (Not Otherwise Classified)

- 25720 - Aviation Equipment, Defense and Homeland Security

- 25729 - Communications Equipment, Defense and Homeland Security

- 25777 - Science and Research Services, Military

- 69079 - Switches, Temperature Pressure

- 71533 - Drawings and Diagrams: Dimensional, Technical, etc.

- 71547 - Manuals: Parts, Personnel, Policy, Purchasing, Training, etc., (Not Otherwise Classified)

- 90514 - Airplane and Helicopter Services (Not Otherwise Classified)

- 90516 - Airplanes, Helicopters and Accessories Maintenance and Repair Services

- 90572 - Spacecraft Services (Not Otherwise Classified)

- 91817 - Aviation Consulting

- 91821 - Business Consulting

- 91828 - Computer Hardware Consulting

- 91829 - Computer Software Consulting

- 91832 - Consulting Services (Not Otherwise Classified)

- 91846 - Feasibility Studies, Consulting

- 91882 - Scientific and Technical Consulting

- 91887 - Procurement Consulting, Including Specification Development and Contract Consulting

- 91888 - Quality Assurance and Control Consulting

- 91890 - Strategic Planning and Consulting

- 91893 - Security and Safety Consulting

- 92018 - Computer Aided Design (CAD) Services

- 92040 - Programming Services, Computer, Including Mobile Device Applications

- 92044 - Risk Management for Software Development

- 92045 - Software Maintenance and Support Services

- 92046 - Software Updating and Upgrading Services

- 92064 - System Implementation and Engineering Services

- 92065 - System Requirements Quality Assurance Review

- 92075 - Technical Writing and Documentation, IT Services

- 92076 - Testing of Systems Infrastructure, Components or Software, IT Services

- 92532 - Electronic Engineering

- 92536 - Engineering Services (Not Otherwise Classified)

- 92555 - Inspecting, General Engineering

- 92567 - Mechanical Engineering

- 92592 - Value Engineering and Value Analysis, Professional

- 95877 - Project Management Services

- 99239 - Electrical Systems Testing Services

- 99255 - Miscellaneous Testing and Calibration Services

- 99270 - Radar Equipment Testing and Calibration Services

- 99271 - Radio Instrument Testing and Calibration Services

- 99275 - Safety Equipment Testing and Calibration Services